This is the english translation of the original Article in brau!magazin Summer 2015.

Summary

Weissbier originated in Bohemia and is part of a 500-year long tradition in Bavaria. Initially being called “weisses beer” (white beer) independent of the type of grain being used it soon developed into the only kind of beer that was allowed to be brewed with wheat and in the summer months. These facts made Weissbier very popular during the 16th – 18th century. At the end of the 18th century Weissbier rapidly decreased in popularity, mainly as a result of the much improved quality of the bottom fermenting brown beers and the later available light beers of pilsner style. Since the 1960ies Weissbeer has undergone a renaissance.

Today Weissbier in Germany is brewed with at least 50% wheat malt. Much more than the grain bill the use of the specific yeast determines the Weissbier character. Key aromas produced by the yeast are the banana flavor isoamyl acetate and the clove-flavored 4-Vinylguajacol. The article details the various methods for influencing the aroma profile. Weissbiers with a pronounced banana flavor are currently high in demand. These beers are rarely produced by industrial breweries due to the short shelf life of isoamyl acetate. Due to the open fermentation at the home brewing scale, banana-flavored beers can be produced without significant technological adaptations. In addition, the article details various methods (high gravity, Maltase process, biochemical adjustments) to enforce an enhanced banana flavor.

Introduction

A few decades back Weißbier was a largely local product of southern Germany. Today it has become the signature drink of the German Beer Culture. Weissbier is brewed with at least 50% wheat malt and fermented with the characteristic top fermenting yeast cultures that produce a complex aroma profile tasting of spices and ripe fruits. This style is often recommended for new home brewers since the cloudy appearance of the beer and the characteristic taste masks brewing mistakes reasonably well. Weissbier brewed properly is however not an easy style for home brewing since the many different flavors and aromas need to be balanced carefully against each other.

After a short summary of the historic development and the prevailing Weissbier styles this article details the possibilities for influencing the aroma and flavor profile of the beer as well as briefly outlining the underlying biochemical background for aroma and flavor generation.

1. History of the Bavarian Weissbier

The Beginnings

The oldest evidence for Weissbier in Germany dates back about 2800 to 3000 years. Most likely these beers had little in common with present day Weissbier which evolved about 500 years ago. Towards the end of the 15th century bottom fermenting beers dominated in Bavaria. These beers were dark (brown/ braunes beer) and due to the lower temperature bottom fermentation had a longer shelf life as the top fermenting beer brewed previously. At about the same time a new beer style of top fermenting, lightly colored and refreshing beers arrived in Bavaria, presumably from Bohemia. These beers were called white beers (weisses Bier) and would today likely be called lightly colored beers (Helles). The light color was achieved by using a lightly kilned malt. Initially the white beers were not associated with a particular grain type and different grain types were used depending on availability and price. Most likely due to local brewing regulations barley was the dominant grain in the malt bill. The result of this was that some of these early “white beers” contained no wheat at all. While wheat beers (Weizen Bier) were well known at the time the name Weissbier originates from the color of the beer rather than the grain bill (Weizen vs. Weissen). The terms "Wheat beer" (Weizenbier) and "White beer" (Weissbier) therefore described the same thing at the end of the 15th century.

Things changed however with the appearance of Duke Wilhelm IV who introduced the so called Reinheitsgebot ("Purity Law") in 1516. The Reinheitsgebot only allowed barley for the brewing of beer. Only 30 years later his son then Duke Albrecht V. allowed the exact opposite; he gave the privilege of brewing with wheat to the Degenberger family who belonged to the nobility. Only five years later he even prohibited the brewing of brown beers in the summer months but allowed the Degenberger family to brew with wheat throughout the summer. This policy not only filled the government coffers but also allowed to tie the influential Degenberger family closer to the ruling Wittelsbacher family. In 1567 Albrecht V. went even further and granted the Degenbergers the wish for having the monopoly for brewing with wheat in Bavaria. The official reasoning was that this would reduce overall wheat consumption. Reinstating the by that time 50 year old, wheat-excluding Reinheitsgebot (purity law) can also be interpreted as an indication that the decree was not widely respected at the time and may only have been implemented for a short period of time.

The Weissbier Monopoly

The privilege to brew Weissbier in reality was not maintained in order to preserve the wheat for the making of bread but it served to protect financial and political interests. For the ruling family of the Wittelsbachers and Duke Maximilian I it was an unexpected bonus that in 1602 the privilege of brewing Weissbier fell back them due to the lack of heirs in the Degenberger family who had owned the privilege previously. Maximilian I was known as a keen financial reformer and he skillfully set the course for benefitting financially from the newly gained Weissbier monopoly. On the supply side he opened numerous Weissbier breweries amongst which is the 1607 founded “Weisse Brauhaus” in Kehlheim better known these days under the name Schneider Weisse. On the demand side he forced the consumption of Weissbier by introducing high taxes on wine which was very popular at the time. He additionally prohibited the import of Weissbier from Bohemia as well as in 1616 the brewing of brown beer in the summer months between the St Georgs day (23rd April) and St Michals day (29th September). The brewing of brown beer in the summer months had already been prohibited by Maximilian’s predecessor Duke Albrecht V. It seems however that this decree was not widely respected. Some sources argue that the brewing prohibition of brown beer in the summer months was enacted since bottom fermenting beers need lower temperatures to be of high quality. Others argue that the prohibition served as a mechanism of fire protection in the dry summer months. Most likely however the summer brewing prohibition of brown beer served to increase demand in Weissbier. In a way one can argue that the Bavarians were forced to become Weissbier drinkers.

According to historians, with the proceeds of the Weissbier monopoly the ruling Wittelsbachers could consolidate their budgets and pay for the defense of their property during the Thirty Years' War. During the most profitable time of the Weissbier monopoly it is assumed that it generated one third of the total income of the state budget. At that time almost every village had a Weissbier brewery from which the Wittelsbachers benefited financially.

Decline of popularity towards the end of the 18th century

Two hundred years later the popularity of Weissbier went in decline. Even though in 1761 the Weissbier monopoly was reaffirmed it could not stop the gradual decline of this beer style. The Weissbier breweries became less profitable and were additionally hampered by the fact that they were only allowed to brew the now more and more unpopular Weissbier. Consequently, many breweries were closed down. In 1798 the Weissbier monopoly was abolished. One of the reasons for the decreasing popularity of Weissbier was the improved brewing technology of brown beer which increasingly matched the quality of Weissbier. As a result, brown beer became more fashionable. With the elimination of summer brewing restrictions for brown beer and the introduction of the Linde refrigerator in the 1870ies the Weissbier demand bottomed out. At the same time the bottom fermenting Pilsner style beer started its ascent to become the most popular beer style.

Renaissance of the Weissbier

Only a handful of the presently existing Weissbeer breweries survived the lack of demand in the 18th and 19th century. Investigating the company histories of nowadays well known Weissbier breweries it is evident that even those breweries adapted by producing bottom fermenting beer for prolonged periods of time. Often the only wheat beer on offer were filtered Kristallweizen (bright Weissbier / crystal Weissbier) which was matching consumer expectation of highly filtrated and bright beers. The renaissance of the typical cloudy Weissbier began in the middle of the 1960ies. This development can partly be attributed to the increasing interest in locally produced, traditional foodstuff but is also credited to Erdinger Weißbräu who used nationwide advertising campaigns to popularize and distribute Weissbier in Germany.

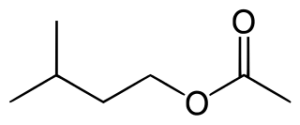

2. Weissbier Styles

The common denominator of the Bavarian wheat beers is the dominant flavor profile of the wheat beer yeast. The classic Weissbeer is characterized by a balance of phenolic (cloves, spices) and estery (banana, pear, red fruits) flavors but a large range of beers from totally fruit dominated to mostly ester dominated beer is currently being brewed. Responsible for the banana flavor is the concentration of isoamyl acetate in combination with a low concentration of ethyl acetate. Increased concentrations of ethyl acetate mask the banana notes and lead to a fruity “bubblegum” flavor.

Darker malts and cara malts can contribute nutty and caramel aromas to the beer. They should not mask the aromas produced by the yeast. Hop forward traditional Bavarian wheat beers are uncommon.

The body of the beer is characterized by a rounded fullness. This is achieved by the increased viscosity, the foam stabilizing properties and the colloidal stability resulting from the wheat malt as well as the relatively high carbonization of up to 8 g/l CO2. Due to the relatively low pH and the well-perceptible carbonic acid, especially light colored wheat beers appear fresh and sparkly. This perception is additionally supported by the high apparent attenuation above 80%. A pronounced hop bitterness is untypical for the style. Phenolic acids can however create a tart – smoky sensory impression.

The sub-categories of Weissbier are determined by the use of colored malts and the original gravity. The following table lists some of the more common styles.

| Light Colored Weizen Beer | Dark Colored Weizen Beer | Light Colored Weizen Bock | Dark Colored Weizen Doppelbock | |

|---|---|---|---|---|

| OG | 1.046 - 1.057 | 1.048 - 1.057 | 1.057-1.070 | >1.074 °P |

| IBU | 9-14 | 10-15 | 15-25 | 15-25 |

| Color | <20 EBC | 25-50 EBC | 15-60 EBC | 30 - 60 EBC |

| Base Malts | Light wheat malt, Pilsner / Vienna, Munich (<30%) | 40-80% dark malt (dark wheat malt, Munich malt), Pilsener malt | Light wheat malt, Pilsner / Vienna, Munich (<30%) | 40-80% dark malt (dark wheat malt, Munich malt), Pilsener malt |

| Speciality Malts |

|

|

|

|

| Residual Alkalinity | 0-10 °dH | 5-10 °dH | 3-10 °dH | 5-10 °dH |

Kristallweizen: Has a similar grain bill to the light colored Weissbier and about 20% more IBUs to accentuate the fresh and sparkly character. The beers are filtered and/or fined by means of gelatine and silica sol in combination with a neutral, well-sedimenting conditioning yeast such as Fermentis CBC-1.

3. Brewing Weissbier

The characteristic taste of the Weissbier is dominated by the esters and phenols. Most important is the compound isoamyl acetate known for its banana flavor and 4-Vinylguajacol (4VG) as well as to a lesser degree 4-Vinylphenol (4VP) that are responsible for the spicy, clove flavor. These compounds are synthesized by the yeast and their abundance can be partly controlled the grain bill and the temperature rest schedule. The following table list the factors that can direct the Weissbier taste towards more a banana or a more clove like flavor. As explained below it is not recommended to completely push the beer in one or the other direction using all the possible adjustment factors.

| More Banana | Balanced | More Clove | Reasons | |

|---|---|---|---|---|

| Grain Bill | >66% wheat mat | 50-70% wheat mat | <50% wheat mat | Less clove predecessor chemical (ferulic acid) with increasing percentages of wheat in the malt bill. Can mask esters under certain circumstances. |

| Original Gravity | High-Gravity | normal | normal | A high OG disproportionally favours the development of esters during fermentation. This means that after dilution of a high gravity fermented wort there can be more esters in the resulting beer compared to normal gravity fermentation. |

| Mash In Temperature | 55°C-63°C | 35-40°C | 35-40°C, pH 6,0 | Ferulic acid production optimum is at 45°C and pH 6,0. Additional conservation of enzymes at mash in temperature of 40°C. Release of ferulic acid and protein degradation at this temperature reduce the banana flavours. |

| Rest Schedule | (55°C protein rest: 5-10 min) 63°C maltose rest: 30-45 min 72°C saccharification rest: 30 min | 45°C rest: 15 min (55°C protein rest: 5 min) 63°C maltose rest: 30-45 min 72°C saccharification rest: 30 min | 45°C rest: 20-25 min (55°C protein rest: 5 min) 63°C maltose rest: 30-45 min 72°C saccharification rest: 30 min |

|

| Brewing water | 0-5°dH | 0-10°dH | 5-10°dH | High residual alkalinities help the formation of ferulic acid at 45°C. Water treatment should potentially be carried out after this rest. The impact on the banana flavor is discussed controversially. Analytically low pH increases banana flavor; sensory it is however reduced. |

| Yeast | W175, Gutmann, W68 | W68, Wyeast 3638, WLP351, WLP380 | W68, W175, Schneider-Hefe | Determining factor. Most experience regarding influencing the taste profile exists for the W68 yeast. W175 has generally a stronger banana flavor but also more ethyl acetate which can lead to a “bubblegum” flavor. |

| Aeration | Do not areate | Areate | Areate | |

| Pitch Rate | 3-8 Mio./ml | 3-8 Mio./ml | 3-8 Mio./ml | The pitch in not a suitable parameter for home brewers to influence the banana flavor. Clove aromas are hardly influenced by the pitch rate (chapter 5) |

| Fermentation Temperature | 16-24°C | 16-20°C | 16-20°C | In general more esters at higher temperatures. The temperature influence on the formation of isoamyl acetate (banana) is not entirely clear. Short fermentation times at high temperatures reduce the banana flavor. Large amounts of fusel alcohols etc. reduce the banana flavor as well. Formation of 4VG (clove) is largely independent of temperature. |

| Secondary Fermentation | 3 weeks @ 20°C | Traditional: 1 week @ 20°C 2 weeks @ 10°C | 3 weeks @ 20°C | Isoamyl acetate and 4VG are increased during warmer secondary fermentation. |

| Fermentation Vessel | open | open | Open or Closed | Open (non-pressurized) fermentation leads to the fermentation of significantly more esters as opposed to pressurized fermentation. |

Brewing considerations for the enhancement of clove flavors

The phenolic compounds 4VG and 4VP have a pleasant spicy /clove like flavor when present in the right concentrations. At too high concentrations the taste can become medical / hard or rough. The normal 4VG concentration in Weissbier ranges from 0,5 to 3,5 mg/l. The odor threshold for 4VG in Weissbier is about 0,8 to 1mg/l. Concentrations above 2 mg/l are perceived strongly.

The promotion of the clove flavor is achieved through sufficiently long cytolysis at an enzymatic optimum temperature of 45 °C. At this temperature the ferulic acid is released from arabinoxylane (ferulic acid rest). This reaction has a high optimal pH range above a normal mash pH. For this reason, rather than increasing the mash pH, a longer rest is chosen. PH adjustments of the mash are typically undertaken after the ferulic acid rest. Typical rest times that promote glove flavor are in the order of 10 - 25 min. This can lead to 4VG concentrations of 1,5 to 2,5 mg/l. A low mash in temperature combined with a slow heating rate through the ferulic acid rest temperature range can already produce perceptible clove flavours above 1mg/l [Her05].

The resulting ferulic acid is mainly converted to 4VG by the POF+ (phenolic off-flavor) yeasts, while approximately 5% are converted to 4VG during the boiling of the wort. The ferulic acid does not convert completely and the relative abundance of phenolic acids are dependent on the specific yeast. The W175 yeast can for example produce 20 to 50% more 4VG. For this reason, the mash schedule needs to be adjusted to the particular yeast used during the fermentation.

Aim 1: 1 – 2,5 mg/l 4-Vinylguajacol

Advice: High percentage of barley, mash in at 37°C and rest for 20 min at 45 °C.

Brewing considerations for the enhancement of banana flavors

Open non-pressurized fermentation in combination with a suitable yeast like the classic W68 can already produce a sufficiently strong banana flavor. High OG or High-Gravity wort can promote the banana flavor further. Higher mash in temperature reduces the clove flavor significantly and additionally promotes the banana flavor.

The combined effect of fermentation temperature, aeration and pitch rate adjustments are more difficult to predict. While higher fermentation temperatures increase the amount of produced esters they also increase fusel alcohols and other by-products. Therefore, the sensory outcome is not always positive. It is best to start the fermentation at 17-18°C and let it rise freely during the fermentation. Some isoamyl acetate is lost to the air during the primary fermentation. Temperatures above 21°C increase the amount of isoamyl acetate during the secondary fermentation.

Tinkering with the pitch rate or the aeration to force a banana flavor should be considered as a last resort treatment. While there can be obviously too little isoamyl acetate there can also be too much of it. In addition, some aromas like ethyl acetate in concentrations above 45mg/l mask the banana flavor and have a much higher shelf life in the resulting beer. If a Weissbier tastes fruity for a prolonged period of time but does not develop a banana flavor it does not automatically indicate a lack of isoamyl acetate. The desired banana flavor simply could have been masked by other flavors. To date there is no conclusive scientific evidence that a change of the pitch rate (normal: 5 mio. /ml) or the aeration forces a banana flavor. It is therefore advised to aim for a healthy, normal fermentation and to change the other parameters to influence banana character of the beer.

Aim 2: 2 – 4 mg/l Isoamyl acetate, Ethyl acetate <45 mg/l

Advice: High percentage of wheat, W68 yeast with 4-5 mio. /ml pitching rate. Pitch at 18°C, let temperature rise freely. After primary fermentation move to secondary and ferment warm for 2-3 weeks.

4. Raw materials / Ingredients

Only 0.6% of the annually produced wheat in Germany is used for malting. The remainder is used for animal feedstock and direct human consumption. Breeding of wheat varieties that are particularly suitable for brewing is therefore not very economical and rare. The wheat varieties currently bred and planted for animal feedstock and human consumption have very high protein and gluten contents. This wheat is largely unsuitable for malting even though the maltsters can partly adjust the malting processes to partly account for high protein content and high viscosity. For this reason maltsters prefer wheat batches that due to climatic or local soil conditions do not fulfill the high protein requirements for animal feedstock and direct human consumption [Nar12]. One can therefore argue that wheat used for brewing is an otherwise rejected product.

Despite the fact that the character of a wheat beer is largely determined by the yeast, the wheat malt contributes some brewing technological peculiarities. Due to the much larger spread in brewing relevant parameters compared to barley it is advisable to investigate the malt analysis of the wheat malt carefully. On average the differences between barley and wheat malt are summarized in the table below.

| Barley Malt | Wheat Malt | |

|---|---|---|

| Foam stability | Lower | Higher |

| Cloudiness stability | Lower | Higher |

| Free Amino Nitrogen (FAN) | Higher | Lower |

| Viscosity | Lower | Higher |

| Clove* | Higher | Lower |

| Banana | Lower | Higher |

*The amount of ferulic acid in wheat malt varies significantly and can approach the level of barley malts.

4.1. Wheat malts

Light wheat malt (3-5 EBC)

Highly enzymatic base malt for light colored wheat beer. Makes up 50-70% of the grain bill with normal lautering systems and up to 100% with alternative lautering systems. Sometimes used in other beer styles (10-20%) for improved head retention and cloudiness. The specific taste of light wheat malts is low but when used in higher percentages it creates the sensory perception of viscosity and body compared to barley.

Dark wheat malt

The taste is often compared to Munich malt of the same color. The use of dark wheat malt is appropriate if the malty character of the beer cannot be solely achieved by using barley (high wheat percentage). Can also be used as the sole wheat malt for light and dark colored wheat beers. In combination with 50% light barley malt light colored wheat beers can still be created. Used up to 70% in the malt bill.

Wheat Caramalt (120 EBC)

The caramel taste of wheat malt up to 120 EBC supports the fruity ester taste and contributes a typical orange color of the light colored wheat beers [Nar09]. Its taste is similar to dark barley cara malts but occasionally is described as a bit rounder due to the missing husks. Used up to 2-3% in light colored wheat beers and up to 15% in dark colored wheat beers.

Roasted wheat malt (900 -1200 EBC)

Due to the missing husks this can best be compared to de-husked barley; e.g. Carafa Special. In analogue to the de-husked barley the taste is described to be rounder. Used up to 5% in dark wheat beer or to intensify the color in light wheat beer (0,5 – 1%)

Oak smoked wheat malt (4-6 EBC)

More subtle smoke aroma compared to beech smoked barley malt. Same percentages in malt bills as light wheat malt. Traditionally used 100% in Grätzer.

Torrified Wheat (3-5 EBC)

Puffed non-malted wheat. Is being converted quicker and more completely in the mash than non-malted wheat. Otherwise similar characteristics to non-malted wheat. Occasionally being described as having a nutty flavor compared to steam rolled wheat flakes. Used up to 15% in non-wheat beers for increased head retention. Used up to 50% in classic styles containing non-malted wheat (e.g. Belgian Wit)

4.2 Brewing water considerations

Wheat beers tolerate a relatively large range in water profiles. Generally, residual alkalinities up to 10°dH are of no concern. The resulting higher mash pH should however be taken into account during the brewing process. The reasons for high tolerance of water profiles are:

- Wheat beer yeasts generate a high pH drop during the fermentation resulting in a satisfactory beer pH even if the wort pH was unfavorable high.

- Since wheat does not have husks the increased solution of polyphenols caused by a high mash pH is restricted to the barley.

- Due to the style typical low hopping the increased hop utilization with increased pH, especially of less desirable compounds, does not create significant problems.

- The higher cloudiness and reduced brightness as a result of higher pH is tolerable for this beer style. Higher turbidity of the post boil wort results however in lower contents of esters in the beer.

High salt contents can reduce the desired soft taste of the beer. Therefore, it is advisable to desalinate the water rather than using brewing salts to increase the mineral content. Considering the aforementioned reasons, a mash or wort acidification is normally not carried out. It has been observed that an acidified mash results in lower quality estery aromas [Her05]. Wort acidification 10 minutes before the end of boil can increase the phenolic and fresh character of the beer, according to Drexler (Weißbierbrauerei Schneider-Weisse).

Even though the brewing process tolerates a large range of residual alkalinities they should be taken into account. Possibilities to counteract the high residual alkalinities without water treatment are:

- Dark malts, cara malt

- Low hop additions

- High percentage of wheat malts

- Healthy, active yeast for a sufficient pH drop

With increased wort pH several chemical reactions including the Maillard reactions are enhanced. Maillard reactions can create nutty, bread like flavors as well as adding significant coloration. This fact can be exploited to create an individual and characteristic Weissbier style simply by adjusting the boiling times and without resorting to darker malts. Since the conversion and evaporation of DMS (corn flavor) is increased for higher wort pH’s a 60-minute boil is normally sufficient. For a nuttier flavor some commercial breweries use boil times of 2 hours and more. In summary the water can be moderately adjusted, the brewing process can be adjusted to the water or a structured yet chaotic approach can be used and as such the water “challenge” offers sufficient scope for individual variation.

4.3. Hops

The main purpose of hop in Weissbier is for preservation purposes. For this reason, it is rare that a German wheat beer has more than 15 IBU. A hop forward bitterness would mark the fruity esters and the spicy phenols. Care has to be taken with hard brewing waters as hop utilization increases disproportionally with wort pH. Suitable hops are the traditional land races (Tettnang, Hallertau) as well as the recently introduced high quality dual purpose varieties such as Saphir, Huell Melon, Mandarina Bavaria and Hallertau Blanc.

Aroma hopping 10 to 15 minutes before the end of boil can be carried out using the aforementioned dual purpose varieties. This will introduce a slightly hoppy initial taste together with a fuller body for the beer. Very late aroma hopping or dry hopping is not typical for Bavarian wheat beer as it masks the typical aromas of the yeast. For purposely hop aromatic wheat beers the new varieties of Huell Melon, Hallertauer Blanc, Mandarina Bavaria or the hop mixture „Fantasia“ are particularly interesting since their fruity/ flowery taste profile suits the typical wheat beer aromas very well.

4.4. Yeast strains

The character of the Weissbier is determined by the yeast. The typical Weissbier yeast strain belongs to the POF+ yeasts which in comparison to other ale yeasts produces significantly more phenolic acid (4-Vinylguajacol (clove flavours)) and isoamyl acetate (banana, pear flavor). The classically used W68 strain produces a balanced profile of 4-Vinylguajacol and isoamyl acetate. The W175 strain produces more 4-Vinylguajacol and isoamyl acetate as well as ethyl acetate which masks the banana and clove flavors at high concentrations. This can lead to a diffuse fruity taste profile. Too high ester concentrations can also produce solvent /medicinal like taste.

Recently there has been some progress in the availability of Weissbier dry yeasts. The origin of the dry yeast strain is however often not clear and the yeast manufactures often use mutations of original strains in addition to strains that broadly resemble Weissbier strains.

Weihenstephan 68

- Available as: White Labs WLP300, Wyeast WY3068, Zymoferm Z033

- High production of Isoamyl acetate

- Medium production of 4VG

- High pH-fall (~1,0 pH)

- Low flocculation

Zymoferm Z034, Typ „Ayinger“

- Likely a mutation of W68

- Slightly more complex fruity taste, otherwise similar to W68

Weihenstephan 175

- Available as: White Labs WLP351, Wyeast WY3638, Gutmann

- High production of isoamyl acetate, as well as high production of ethyl acetate. Tends to produce ”bubblegum” flavours

- High production of 4VG

- Low pH-fall, therefore less acid/ fresh compared to W68

- Low floculation

WLP380 Hefeweizen IV Ale Yeast

- More phenolic

- Increased production ethyl butyrate (pineapple)

- Very low flocculation

Wyeast 3333 German Wheat

- Balanced strain. Tendency towards more phenols and less banana

- High flocculation

- Suitable for Kristallweizen (crystal wheat beer)

Wyeast 3056 Bavarian Wheat

- Mix of Weissbier strain with neutral ale strains to produce low amounts of esters and phenols

- Style guide: Crossover between Weissbier and American Wheat, dark Weissbier, Weizenbock

Dry yeast

- Danstar Munich Classic: Strain Doemens 479. Has been introduced successfully in many Weissbier breweries.

- Mauribrew Weiss: Classis Bavarian Weissbier displaying well balanced clove and banana flavours. Slight tendency to produce sulfuric notes.

- Mangrove Jack’s Bavarian Wheat: Balanced Weissbier with subtle banana and rather low clove flavours

- Fermentis Safbrew WB-06: Mixed results

- Danstar Munich Wheat: Mixed results

5. Infusion vs. Decoction Mashing

In order to produce the characteristic flavours of Bavarian Weissbier it is necessary to use a multi-step temperature mash schedule. This can be achieved by infusion mashing or via two or three stage decoction mashing. Decoction mashing is still well established in Weissbier breweries (2011: 40% of all breweries). Hermann [Her05] could not identify analytical or sensory differences between Weissbier produced by decoction and infusion mashing. Weissbier produced via decoction mashing did however show better head retention and higher stability of the turbidity. Additional information regarding the mashing method can be found here: (Auswahl eines Maischverfahrens unter „Infusion vs. Dekoktion — der aktuelle Stand“ // in German only)

High Gravity brewing

High gravity wort disproportionally favors the formation of esters during fermentation. By fermenting wort with an OG of 1.061 to 1.063 and then diluting it post primary fermentation to 1.048-1.055 with softened water one can achieve higher ester concentrations. These concentrations could not have been achieved using wort in the 1.048-1.055 range.

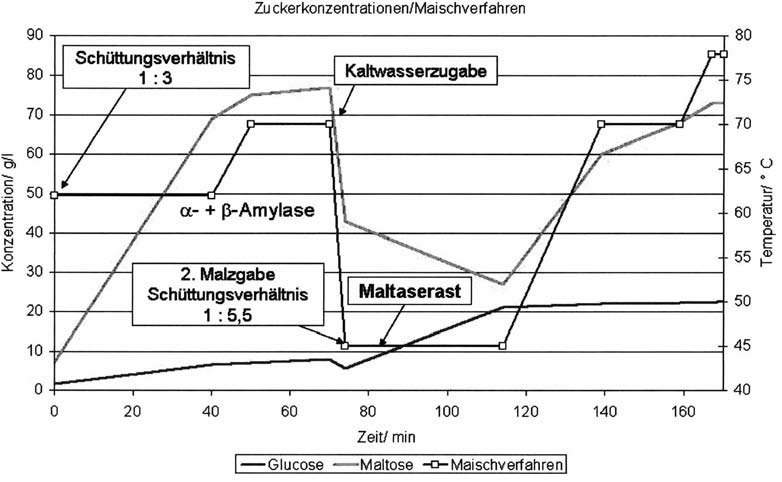

Maltase process / Herrmann process for increased ester production

In 2005 Herrmann [Her05] presented an elegant way to enhance the ester production in Weissbier. He could show that by pushing the wort sugar proportions towards 40% glucose and 60% maltose the production of isoamyl acetate is significantly increased. The underlying reason for this is not entirely clear. It is currently being proposed that the stress point for the yeast caused by the forced conversion from glucose to maltose metabolism is delayed. The later the yeast reaches this stress point the more substrate for the production of esters has already been provided from the wort. At the same time, it is being discussed that glucose presence favors the activity of the ester-producing enzymes. An additional explanation being discussed is that at the time of the aforementioned delayed glucose deficit all oxygen (which reduces ester production) has already been consumed.

Herrmann developed his method mainly for the brewing industry and their large conical fermentation vessels where ester production is typically reduced. Nevertheless, the method can be used with some adaptations by home brewers. The proportionally higher production of isoamyl acetate compared to ethyl acetate and the suppression of “green-beer taste” by the reduction of acetaldehyde can produce a Weissbier with a lasting banana flavor that can be drunk after minimal lagering /conditioning time. Since 4VG is much more resistant to ageing than isoamyl acetate the beer will attain a more classical Weissbier taste with increased lagering /shelf time. Weissbier produced without the low temperature mash-in rests will often show a rather neutral taste after a few weeks in storage.

The maltase process draws its name from an additional rest at 45°C which is the optimum temperature for the maltase enzyme. This enzyme splits the double sugar maltose into two glucose molecules. The substrate for this reaction is the maltose which is produced during the maltose rest above 60°C. At this temperature any maltase enzyme would have already been destroyed. For this reason an additional step is necessary where the temperature is reduced to 45°C and fresh, enzymatic malt is added. The additional process step can increase the entire mashing schedule to over 3 hours. As discussed above, open fermentation can already produce enough banana flavor and the addition of a maltase process could produce too many masking compounds leading to an overall negative sensory result. Nevertheless, it is worthwhile trying out this process if one is set to produce a strongly banana-flavored Weissbier.Home brewers can significantly simplify the maltase process by mashing in at 45°C adding about one third of the extract or 20% of the grain bill in the form of readily available malt extract.

6. Formation of Esters in Detail

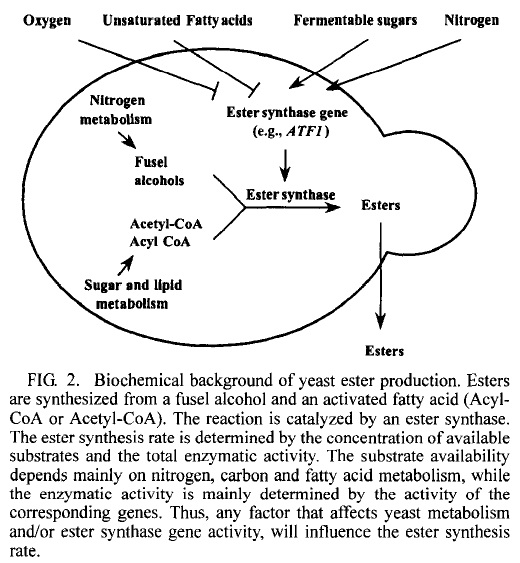

Isoamyl acetate which is responsible for the typical banana flavor is produced through an enzymatically catalyzed esterification of acetyl-CoA and isoamyl alcohol. Two factors are decisive: firstly, the activity of the relevant enzymes, and, secondly, the amount of substrate (i.e. isoamyl alcohol and acetyl-CoA). For a long time, research has focused on the substrate, and thus has taken into account conditions which affect the amounts of higher alcohols and acetyl-CoA.

The amount of acetyl-CoA is closely linked to yeast growth. As long as the yeast cells encounter favorable growth conditions, they require acetyl-CoA for the build-up of biomass. Consequently, acetyl-CoA does not act as a substrate for ester formation. This model provided a valid explanation why measures to reduce yeast growth, such as low levels of aeration or FAN would lead to increased amounts of esters. However, this model could not explain why excess CO2 pressure would reduce ester levels, despite having been shown to slow down yeast growth.

Also, results indicating the amount of higher alcohols would act as a limiting factor for ester formation were not entirely unequivocal. Whilst some results indicated that an addition of isoamyl alcohol would lead to strongly increased amounts of isoamyl acetate, it is not entirely clear why other factors that would lead to higher amounts of higher alcohols, such as high levels of oxygen or increased convection during fermentation would lead to lower ester contents.

Therefore, more recent research efforts have focused more strongly on alcohol acyl transferase activity (Fig. 3). Besides individual genetic factors of yeast strains, their activation and, thus, ester synthesis is controlled through a complex reaction on many other factors, such as carbohydrates, oxygen, nitrogen and other nutrients [Ver03]. Some of these factors shall be looked at more closely below.

Aeration

Figure 3: Schematic Representation. ATF-catalyzed esterification of acyl-CoA / acetyl-CoA with higher alcohols. Decisive factor not only substrate but especially enzymatic activity.([Ver03])

Pitching Rate

Pitching rate seems to have a similar effect as aeration. Increased pitching rates increase ester contents, and so do extremely low pitching rates of <0.5M/ml (which cannot be recommended for practical purposes). The impact on isoamyl acetate seems to be more complex, however, and sometimes increased total ester contents coincided with reduced levels of isoamyl acetate. This may have a particularly strong impact as the predominant ethyl acetate can have a masking effect on isoamyl acetate. A possible explanation may be the delayed onset of higher alcohol synthesis, including isoamyl alcohol as precursor for isoamyl acetate. These results are supported by practical observations, that very fast Weissbier fermentations of less than 72 hours exhibit low ester contents [Sch13].

Free Amino Nitrogen (FAN)

As the yeast produces isoamyl alcohol from the amino acid leucin, the leucin ratio as part of the entire amino acid content is a decisive factor for the production of isoamyl alcohol, and, thus, isoamyl acetate. This ratio is already a fixed feature of the employed wheat strain and cannot be influenced in the brewhouse. The leucin content may vary strongly with the wheat strain, however, and the brewer may hit a "lucky punch" when purchasing the "right" batch of wheat malt. As analyses are not routinely being carried out, it might be worthwhile to stockpile higher amounts of one particular batch in order to adapt one's process.

The results referring to total FAN are somewhat controversial. On the one hand, additional FAN acts as substrate for ester synthesis, on the other hand, increased FAN levels have been shown to lead to decreased levels of isoamyl acetate. As such, one may assume that higher levels of proteolytic modification with the purpose of more "banana" should not be targeted in the malthouse. This concurs with the general recommendation of higher mash-in temperatures (>55°C) for more banana-flavoured wheat beers.

References:

- [Her05] Entstehung und Beeinflussung qualitätsbestimmender Aromastoffe bei der Herstellung von Weißbier. Herrmann, M., Dissertation, TUM, 2015

- [Nar12] Die Bierbrauerei: Band 1: Die Technologie der Malzbereitung. Narziss, L., Wiley-VCH, 2012

- [Nar09] Band 2: Die Technologie der Würzebereitung. Narziss, L., Wiley-VCH, 2010

- [Nit91] Investigations into Optimizing Wheat Beer Quality. F. Nitzsche, Brauwelt, Band 32, 1991

- [Pla05] Influence of glucose and oxygen on the production of ethyl acetate and isoamyl acetate by a Saccharomyces cerevisiae strain during alcoholic fermentation. C. Plata, J.C. Mauricio, C. Millán and J.M. Ortega, World Journal of Microbiology & Biotechnology, Vol. 21, 115 – 121, 2005

- [Ver03] Flavor-Active Esters: Adding Fruitiness to Beer. Verstrepen, K.J. et al., Journal of Bioscience and Bioengineering, Vol. 96, No. 2, 110-118, 2003

- [Sch13] Aromaprofile ausgewählter Weizenbier-Hefestämme. Schneiderbanger, H. et al, Brauwelt, Nr. 10, S. 267-270, 2013

Pingback: Weissbier釀造重點摘要 – Vito's Blog